B Slide rotary unit on shaft sleeve and set the back of the rotary unit on the second scribe line as determined in step 8. If you are unable to identify the seal it will be necessary for you to.

Back To Basics Mechanical Seals Pumps Systems

Type 5610 and 5610Q seals are designed for versatility and can be assembled in various ways.

. Therefore standard mechanical seals are used only for a pressure up to 10 bar. Mechanical seals are designed to overcome these drawbacks. Mechanical seal that keeps gas from escaping while rotating with the shaft.

This mechanical seal is designed to operate in a liquid so the heat energy it creates is adequately removed. Mechanical seal and is defined as In practice k values are selected between 065 and 12. 12 Design An essential mechanical seal contains three sealing points.

Mechanical Seal Drawing Pdf. Unlike an O-Ring seal the hydraulic diameter of a bellows seal is not a fixed geometric value. The stationary part of the seal is fitted to the pump housing with a static seal this may be sealed with an o-ring or gasket clamped between the stationary portion and the pump housing.

The manufacturer listings are alphabetical refer to pages 7 - 13. All these seals are manufactured to Springer Parts LLC. Packing Although mechanical seals had been around for many decades by 1955 industry had converted only a small percentage of pumps from packing to mechanical seals.

Many Others US. Manufacturer and their affiliates andor subsidiaries. Set screw the rotary unit to the shaft sleeve if seal is supplied with holding clips remove at this time.

The seals are arranged by shaft size from smallest to largest. See outline drawing and seal housing port identification schematic found in the Seal Environmental Control System section of this manual. Identify the correct replacement seal.

Study the engineering layout drawing to confirm the proper seal arrangement for the pump being used. The Worlds First and only Split Double Seal. For higher pressures balanced mechanical seals are used.

A mechanical seal is a device that helps join systems or mechanisms together by preventing leakage eg. 120 GENERAL SAFETY NOTES Any person being involved in assembly disassembly start-up operation and maintenance of the mechanical seal must have read and understood this operating manual and in particular the safety notesWe recommend the user. If properly Installed in the same application the Springer Parts LLC.

522 Lubricate the shaft of the machine through the use of a liquid compatible with the gasket in order to assist the sliding. A Place gland with stationary seal face and gasket on the pump shaft. Probably the most widely recognized and also most common mechanical seal used in general service low pressure applications.

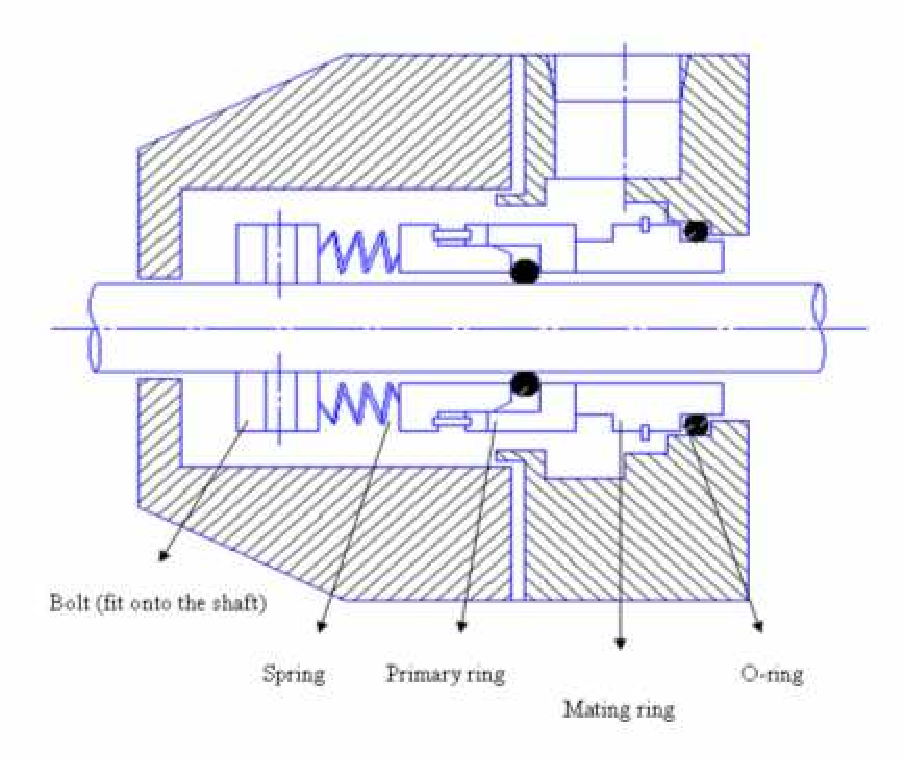

This principle is illustrated in the sketch below. All symbols and abbreviations shown are not necessarily used on the drawings diffuser grille designation amount of air neck size or width x. Dry gas seals are basically mechanical face seals consisting of a mating rotating ring and a primary stationary ring Fig.

The seal between the rotating 3 and stationary faces 1. Fig1 The main components of a mechanical seal are the seal rings on which a mechanical force is acting generated by springs or. To assure satisfactory operation handle seal with care.

This is due to various reasons. Mechanical seal drawing pdf To apply basically stick on the nails we like to help keep them at the base of our nail beds and established with very clear topcoat. In order for mechanical seals perform extended time periods with low surfaces friction is necessary good maintenance monitoring for hydrodynamic lubrication.

At Utex we refer to this type as RS-1 The assembly shown in the pump is configured with a. The mechanical seal Mechanical seals have the purpose of preventing leakage of a fluid liquid or gaseous through the clearance between a shaft and the fluid container. Drawingdetail number sheet number re.

Mechanical seals c a t a l o g cartridge seals metal bellows cartridge seals high pressure pipeline seals composite cartridge seals rotary units metal bellows multi spring outside mount stationary seats o-ring block clamp l type utex industries inc. SEAL TYPE The mechanical seal shown in the pump photograph is a Type 1 mechanical seal. An eye fixed-catching style has never been much easier.

Mechanical seal selection The spring is in the product. 04 to 28 scfmin leak rate significantly less than from wet seals Cost-effective option for new compressors Significant capital costs and downtime for retrofitting compressors. The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets.

4 Global Presence Local Support Responsiveness Worldwide. To quickly design detailed drawings for parts or seals. 60 Table of Contents.

A stationary seal may also be referred to as packing. Mechanical Seals76 Pump Disassembly Replacement Parts. A mechanical seal has 4 main sealing points indicated by orange circles as per Figure 3.

Taking sealing technology beyond. The following instructions describe the standard configurations. With this level of local customer focus the Quick Response Centers are ready to respond to.

Mechanical Face Seal Replacement How To Use This Catalogue Locate the manufacturer of the equipment. The seal between the rotating member and shaft or shaft sleeve 4. During operation grooves in the mating ring Fig.

2m171 1 drawing note reference ie notes by symbol miscellaneous drawingdetail reference abbreviations general notes mechanical symbols and abbreviations note. THE PROTECTION OF A. Without disturbing the scribe line B wipe the shaftsleeve clean.

The seal between the stationary member 1 and stuffing box face ie. 521 Make sure that the mechanical seal is corresponding to the assembly drawing. 4 generate a fluid-dynamic force causing the primary ring to separate from the mating ring creating a running gap between the two rings.

Mechanical Seal Piping Plans. 9 Install the mechanical seal in the pump. From the installation drawing determine the distance from the seal chamber face to the seal set length and scribe line B onto the shaft sleeve at this distance.

Seals will perform as well as or better than the original manufacturers seals if properly installed in the same application. The product pressure acts additional to the spring on the rotating seal part. In a plumbing system containing pressure or excluding contamination.

With a lower k value the safety against thermal overload will increase but the mechanical seal may also lift off more easily. REPLACE YOUR CURRENT DOUBLE SEAL. Install a system to control the seal environment.

In this case two mechanical seals are arranged in series. It is also influenced by. This is known as the primary seal.

And are guaranteed to. To install a seal the pump would have to be taken off-line and disassembled. Mechanical seals often have one face of a suitable solid lubricant such that the seal can still operate for a period without the fluid film.

PPC seals and seal parts are guaranteed to be free from defects in material and workmanship. Operating Manual MFL85Ndw-00 page 4 23 en MFL85Ndw-00 April 28 2016 Rev.

Sru Hyclean Double Mechanical Seals Complete Pdf

Pt Tjm Internasional Mechanical Seals

Experimental Analysis Of Mechanical Seal Design With Enhanced Thermal Performance Semantic Scholar

Pt Tjm Internasional Mechanical Seals

0 comments

Post a Comment